Land Swap Threat to Westchester and NYC’s Water

by George Klein, posted April, 2024

In brief: Westchester County Airport is polluted with highly toxic PFAS chemicals. Yet, the Westchester County Board of Legislators on April 8, 2024 approved a land exchange, “the swap”, of 13.4 acres owned by the Westchester Joint Water Works, for the same sized parcel at the airport. This will allow WJWW to build a water treatment plant at the airport.

The problem is that the construction project site is located within the watershed of the Kensico Reservoir. A watershed is the area surrounding a body of water, and any precipitation falling there ends up in that body of water, so a watershed is a basin.

This project could easily dislodge these toxic PFAS chemicals into the nearby Kensico Reservoir. The Kensico is the source of drinking water for 9 million people, including most of Westchester’s population, and many more in NYC. PFAS chemicals have contaminated the drinking water supply for hundreds of communities around the U.S. According to recent findings by the EPA, PFAS are toxic at even the lowest detectable levels and it is extremely expensive to remove them from the water.

This is an environmental and public health issue.

The 4/10/2024 New York Times article “E.P.A. Says ‘Forever Chemicals’ Must Be Removed From Tap Water” is just the latest evidence that federal and state regulators are judging PFAS to be ever more dangerous to our health. “Exposure to PFAS has been associated with metabolic disorders, decreased fertility in women, developmental delays in children and increased risk of some prostate, kidney and testicular cancers,” says the article.

Our Board of Legislators could avoid this harm simply by insisting that the WJWW project be sited outside of the Kensico Reservoir watershed.

Sierra Club, Purchase Environmental Protective Association, Purchase Friends Meeting, the Coalition to Prevent Westchester Airport Expansion and others oppose the WJWW project at the location planned, specifically because it is within the Kensico Reservoir watershed.

We acknowledge WJWW’s need to build the treatment plant, but judge the risk of contamination by PFAS pollution to the water in the Kensico from soil and groundwater disturbance from the construction at this location is too great. However, the Board of Legislators judges this risk worth taking, considering the urgency of the project, which will benefit 80,000 - 100,000 people served by WJWW.

The 4/8/2024 vote was 15 in favor, 1 against, and 1 abstention. The legislator who voted against the project had concerns about the water in the Kensico Reservoir.

An ounce of prevention would surely go a long way here, considering the risk to public health and to the public’s wallet.

We are continuing our efforts against this project.

The Examiner News did a good article on the situation:

https://www.theexaminernews.com/westchester-approves-land-swap-for-new-filtration-plant-near-airport/

If you would like to pitch in, please email me at lowerhudson@gmail.com.

Governor Hochul signs the Birds and Bees Protection Act into law!

Sierra Club issued the following press release on December 22, 2023:

Sierra Club Statement on Governor Hochul Signing Birds and Bees Protection Act

Caitlin Ferrante, caitlin.ferrante@sierraclub.org; Roger Downs, roger.downs@sierraclub.org

ALBANY, NY -- Today, Governor Kathy Hochul signed the Birds and Bees Protection Act into law. The new law will eliminate 80-90 percent of the toxic class of pesticides called neonicotinoids, or neonics for short, from entering New York’s environment. The law will prohibit the use of unneeded neonic coatings on corn, soybean, and wheat seeds and non-agricultural lawn and garden uses.

Long connected to mass loss of the bees critical to New York’s agricultural economy and environment, neonics have emerged as the most ecologically destructive pesticides since DDT. In May, the U.S. EPA made the unprecedented finding that neonics are driving 200+ species toward extinction, and the pesticides have been linked with mass losses of birds, the collapse of aquatic ecosystems, and birth defects in deer. New York health experts have also raised alarms about the continued use of neonics -- the pesticides extensively pollute New York water supplies and New Yorkers’ bodies, with recent research documenting near-ubiquitous and steadily rising levels of neonics in pregnant women.

Due to legal loopholes, the New York Department of Environmental Conservation exercises no regulatory authority over neonic-coated seeds. Support for the Birds & Bees Protection Act has been widespread with over 370 New York farms, businesses, and organizations having called on Gov. Hochul to sign the bill into law.

In response, Sierra Club Atlantic Chapter Conservation Program Manager Caitlin Ferrante released the following statement:

“The Sierra Club applauds Governor Hochul for protecting New York families and our environment by signing the Birds and Bees Protection Act into law. Using sound science as a backbone for the policies that protect NY’s pollinators, water, and soil health will ensure our communities are safer for generations to come. We thank the Governor for her nation-leading action.

“The Sierra Club would also like to thank Assemblymember Glick, Senator Hoylman-Sigal, Senator Harckham, Assemblymember Solages, Assemblymember Reyes, Majority Leader Stewart-Cousins, and Speaker Heastie for their tireless leadership in getting this bill across the finish line. This new law will have a lasting impact on the environment and New Yorkers will be safer and healthier thanks to their leadership.”

The Municipal Solid Waste Conundrum

by Laura Burkhardt

The Westchester Alliance for Sustainable Solutions (WASS) in Westchester County is currently engaged in a campaign to shut down the Wheelabrator Westchester (“Wheelabrator”) Waste-to-Energy (WTE) facility in Peekskill, which combusts the county’s municipal solid waste (MSW). A summary of some of the complaints, with responses by Wheelabrator, was published in March 2023.

Environmental groups oppose incineration of MSW “because of its adverse environmental and health effects and the destruction of materials that could be conserved while saving energy through other management methods.” But shutting down the currently operating WTE facility will also have environmental consequences. Let’s take a closer look at the issues.

Arguments for closure.

-

Wheelabrator emits large amounts of greenhouse gases and pollutants. CO2e emissions for Wheelabrator for years 2017 to 2021 are shown in Table 1 (source: EPA Facility Level GHG Emissions Data)

Table 1. Emissions for Wheelabrator Westchester 2017 to 2021

-

CO2e = carbon dioxide equivalents, a unit of measurement used to compare the impact of different greenhouse gases (GHGs) on the environment. CO2e provides a unified way to express the contribution of each GHG to climate change, i.e., it tells us the amount of CO2 needed to produce the same amount of warming that other GHGs create.

GWP = Global Warming Potential, which allows comparisons of the global warming impacts of different gases.

Biogenic CO2e emissions are defined as CO2 emissions related to the natural carbon cycle, as well as those resulting from the harvest, combustion, digestion, fermentation, decomposition, or processing of biologically based materials.

-

The facility is 39 years old. The average retirement age of a WTE plant like Wheelabrator is estimated to be 23-27 years.

-

The coal ash resulting from the combustion process is taken to a landfill in Connecticut which is located near wetlands and the Quinebaug River.

-

A February 2017 report from NY State Department of Health compared Peekskill to surrounding communities and reported high rates of asthma in Peekskill, respiratory cancers, death due to cardiovascular disease and high incidents of low birth weight.

Response to arguments for closure

-

Yes, Wheelabrator does produce a lot of CO2e emissions. But the facility also makes positive contributions to the economy. And over the past 5 years its emissions have decreased by 12.5% (as shown in Table 1 above). This decrease can be attributed in part to continual upgrades for air quality control that have been made to the facility (see next item).

-

Although the facility is 39 years old, it is continually being upgraded with new technologies for controlling air quality. Since 2013 these improvements include devices to neutralize acid gases such as sulfur dioxide and hydrogen chloride, filters that remove over 99.5% of particulate and trace metals, systems that enhance the control of mercury and trace organics, and systems that reduce nitrogen oxides. Wheelabrator’s emissions are well below the limits established by EPA, as shown in the following table for 2022. The useful life of a WTE plant is not necessarily determined by its age.

-

Column 3 = EPA Limits for Existing (2009) Municipal Waste Combustors

Column 4 = Title V Air Permit Limits for WWLP

NOx = Nitrous oxides PM=Particulate matter SO2=Sulphur dioxide HCl=Hydrogen chloride

CO=Carbon monoxide Hg=Mercury Cd=Cadmium Pb=Lead

-

Wheelabrator Westchester is currently investigating alternate ways to dispose of the coal ash produced by the combustion process. Coal ash is widely used as an ingredient in hydraulic-cement concrete because it improves many desirable properties of concrete. Using coal ash to make concrete is one way to physically change the coal ash and encapsulate the toxic elements while creating a valuable material.

-

The March 2023 article says “A February 2017 report from NY State Department of Health … reported high rates of asthma in Peekskill, respiratory cancers, death due to cardiovascular disease and high incidents of low birth weight.” This statement needs clarification and context. Although the report was issued in February 2017, it covered the years 2010 to 2013.

In contrast to the February 2017 report, a Community Air Screening project in 2017 took air samples from 4 different areas in Peekskill: (1) Main St., (2) the Wastewater Treatment Facility, (3) Pipeline Metering and Regulating Station, and (4) Charles Pt. Park (i.e., the WTE facility). (So there is more than one source of pollution in Peekskill.) There were 28 different substances measured. With respect to the WTE facility the final report says, “The measured results for the air toxics from this short-term assessment would not be considered a potential health threat or an immediate public health concern”. A full report is available online.

We also note this observation from a study of five trash incinerator plants by the National Institute of Health: “Making a scientifically valid connection between operation of an incinerator and resulting disease within a population is a difficult undertaking, requiring the combined efforts of toxicologists, epidemiologists, chemists, physicians, and persons in other disciplines.” In other words, ascribing health problems in a community to emissions from a single site is not a straightforward matter, especially if the community has more than one source of pollution.

Contributions of Wheelabrator Westchester to the economy

-

It reduces the amount of our MSW. In 2020, Wheelabrator Westchester combusted 659,116 tons of waste, resulting in 152,613 tons of toxic ash, about 23% of the waste tonnage.

-

It generates electricity. By combusting MSW, it generates over 300 GWh of electricity annually. In 2020 it generated 369.9 GWh; it 2021 it generated 323.1 GWh. This is enough to power about 30,000 homes.

-

Metals are recovered from the coal ash (12,000 tons in 2016).

-

Beginning in 2013, the plant has piped steam directly to White Plains Linen, via a newly constructed steam line. White Plains Linen is a 100,000 square foot commercial laundry facility adjacent to the plant and has converted its natural gas-fueled laundry equipment and room heating systems to steam. This enables the laundry to significantly reduce the amount of natural gas it uses to make steam and hot water, from 1 million therms per year to less than 90,000 therms per year. The reduction in natural gas usage will eliminate 4,775 metric tons of greenhouse gas emissions annually, according to Wheelabrator.

What are the consequences of closure?

The consequences of closure are:

-

An alternate source of electricity will be needed;

-

White Plains Linen will need another source of steam;

-

Another method will be required to dispose of our MSW.

What are the alternatives for generating electricity?

In 2021 Wheelabrator Westchester generated 323.1 GWh of electricity. It is assumed that any replacement amount of electricity would come from renewables (solar, wind, hydropower). If Wheelabrator were closed, it would require, for example, roughly 610 acres of solar farms (an area about 3/4 the size of New York City’s Central Park) to generate 323.1 GWh of electricity annually.

What are the alternatives for supplying steam to White Plains Linen?

Since White Plains Linen has converted its laundry equipment and room heating systems to steam, ideally some other means would be employed to produce this steam. If no steam replacement was practical, the company would probably need to revert back to natural gas for its operations.

What are the alternatives for disposal of MSW?

The Technical Alternatives. Our research indicates that there are currently no feasible technical alternatives to replace Wheelabrator Westchester. Technologies such as hydrothermal carbonization of organics, plasma gasification, and pyrolosis are sometimes mentioned as possible replacements, but these technologies can also have harmful emissions, may not be practical at large scale, and may not yet be successfully commercialized. A brief survey of these technologies is available upon request from the author.

The Landfill Alternative. If Wheelabrator Westchester closes, the closest currently available option would be a landfill in Syracuse, which would entail a 495 mile round trip by 60 trucks every day. Transportation to the landfill would produce emissions: an empty garbage truck emits 3.5 kg of CO2 per mile. Sixty trucks driven over 495 miles a day for 365 days is 37,942 metric tons per year. Additionally there is the noise, dust and traffic disturbance that occurs when large numbers of garbage trucks are driven through communities on a daily basis. Further, the 383,302 tons of biogenic CO2e currently emitted by Wheelabrator (see Table 1 above) would now be emitted by the landfill.

Were the landfill in Syracuse to become unavailable, the next closest one would be in Pennsylvania.

The Recycling and Reduction Alternative. Increased recycling of paper, glass, and plastics and reduced use by consumers of single-use products are viable alternatives for disposing of MSW. Although the Material Recovery Facility in Yonkers processes about 90 percent of the residentially collected recyclable material in Westchester County and sells it to recycling operations, we are told that the market for recyclables has dried up, and many private haulers in Westchester County who collect from businesses and non-residential operations do not separate recyclables, instead sending all MSW to Wheelabrator. We must work to create a larger market for recyclables. Food scrap recycling programs that are being implemented in many municipalities are an important step in this effort.

Reduction efforts, especially of single-use plastics, are extremely important. A recently passed single-use foodware law in Westchester County restricts delis and restaurants to providing individual plastic foodware packages only upon request. Delis and restaurants also need to make use of returnable reusable containers for takeout food; new regulations that enable customers to bring their own containers for takeout are essential. Individuals can help by reducing their daily use of single use plastics, such as cutlery, cups, lids, straws, bags, and beverage bottles (including single use water bottles).

Less plastic packaging would also go a long way in reducing the amount of waste we generate. Buying food in bulk or avoiding items with a lot of disposable packaging are strategies that we as individuals can follow. We must also work to get companies to reduce their use of plastic packaging; paper-padded envelope mailers and cardboard boxes, for example, are accepted by most curbside recycling programs, while bubble-lined paper mailers and plastic bags are not.

Conclusions

The solution for disposing of municipal solid waste is not simple. At the present time we see recycling and reduction, while not a complete replacement for the WTE facility, as the best actions to take. As individuals each of us must focus on reducing, reusing, and recycling, using all possible means — including messaging, lawsuits, protests, all types of media — to persuade institutions and governments to do the same.

Sources

-

Conversations with and emails from Commissioner Louis Vetrone of the Westchester County Department of Environmental Facilities (DEF), which is responsible for waste management in the county

-

https://www.nyiso.com/documents/20142/2226333/2022-Gold-Book-Final-Public.pdf

-

Health effects from hazardous waste incineration facilities: five case studies - PubMed (nih.gov)

Protecting pollinators begins in your own backyard!

Did you know that 35% of our food grows as a result of the work done by our pollinators? That's one in every three bites! Unfortunately, the birds, bees and butterflies that carry out this essential service are in serious trouble right now due to habitat fragmentation and widespread pesticide use.

One of the most effective ways to help pollinators is to transform part of your yard into a pollinator garden full of their favorite native plants. Public spaces such as parks and community buildings can also make excellent sites for these gardens, which provide food and form critical habitat corridors for pollinators. Over 200 communities in NY and nearby states have joined in this exciting, restorative work. The Pollinator Pathway project offers all the information you need to get started.

https://www.pollinator-pathway.org/

For more information about pollinators and what people can do to protect them, visit the Pollinator Network at Cornell’s College of Agriculture and Life Sciences:

https://cals.cornell.edu/pollinator-network

Coalition to Prevent Westchester Airport Expansion

The Coalition’s purpose is to ensure that the County’s primary objective in making airport policy should be to operate the airport to “do no harm” to its surroundings. The coalition includes:

- Federated Conservationists of Westchester County (FCWC)

- Purchase Environmental Protective Association (PEPA)

- Citizens for a Responsible County Airport

- Westchester for Change

- National Quiet Skies Coalition

Visit the coalition's website: coalition-to-prevent-westchester-airport-expansion.org

Long Duration Energy Storage

Long Duration Energy Storage Technologies: A Survey

Laura Burkhardt

August 8, 2022

Jeff Schumann, Chris Burger, and Valdi Weiderpass contributed to this report.

NOTE: The opinions expressed in this report are solely those of the author and are not necessarily endorsed by Sierra Club.

- Introduction

- Definition of Terms

- Comparison of the Technologies

- Details about the Various Technologies

- Conclusions

- Introduction

The main argument against a renewable energy grid put forth by fossil fuel and nuclear proponents is that the wind is not always blowing and the sun is not always shining. Ergo there will be periods, such as extended cold spells, summer heat waves, days of continual rain, when the grid will not be able to provide needed electricity. During these times we need firm dispatchable resources, i.e., natural gas, oil, nuclear energy, to power the grid – or so the argument goes.

But there are alternatives to these firm dispatchable resources. One of the most important is long-duration energy storage. Lithium-ion batteries currently dominate the energy storage market, but they are better suited for short-term storage because the charge they hold dissipates over time. We will need storage that can provide electricity to the grid for many hours or days and even weeks.

There is a growing list of contenders, using diverse technologies and at different stages of commercialization. This paper will first describe existing, well-known technologies and then move on to more recent and less well-tested developments.

- Definition of Terms [1,2]

This section defines the terms that are used when discussing and comparing storage technologies.

Power and Energy – Power, usually measured in kilowatts (kW) or megawatts (MW), is the load that a storage system or generator can serve at any instant in time. It is important to distinguish this from energy, measured in kilowatt-hours (kWh) or megawatt-hours (MWh), which is the amount of power that can flow over time.

Capacity – This term means something different for a power plant vs. a storage system. The capacity of a power plant (power capacity) refers to the amount of power that it can generate (MW). But the capacity of a storage system (energy capacity) refers to the volume of energy it can store (MWh).

Storage Duration. Storage duration is the amount of time storage can discharge at its power capacity before depleting its energy capacity. For example, a battery with 1 MW of power capacity and 4 MWh of usable energy capacity will have a storage duration of four hours.

Storage Duration (hours) = Energy Capacity (MWh) / Power Capacity (MW)

This concept is also referred to as discharge time, defined as the amount of time a storage technology can maintain its output. In Table 1 below, the term Discharge Time is used; values for power and discharge time are given but not the values for energy capacity.

Depth of Discharge - Depth of discharge is the percentage of capacity discharged. Deep discharges (>50% DOD) shorten the lives of some batteries, while others operate best this way.

Cycle life/lifetime is the amount of time or cycles a battery storage system can provide regular charging and discharging before failure or significant degradation.

Energy Density is the amount of energy stored in a given system or region of space per unit of volume. High energy density is better than low energy density because it requires less space to store or hold a given amount of energy.

Levelized Cost of Storage (LCOS). This is the cost of kWh or MWh of electricity discharged from a storage device when accounting for all costs incurred and energy produced throughout the lifetime of the device.

Adiabatic/Isothermal [2a, 2b]. These concepts are used in more advanced forms of compressed air energy storage (CAES) as ways of overcoming some of the limitations of the original systems.

- An adiabatic process is a thermodynamic change whereby no heat is exchanged between a system and its surroundings. In an advanced CAES implementation the heat generated by the compression process is captured and fed back into the compressed gas during the expansion phase, thus improving the system’s round trip efficiency and eliminating the need to reheat with natural gas.

- An isothermal process is one in which the temperature of the system remains constant. Isothermal CAES requires the heat to be removed continuously from the air during the compression cycle and added continuously during expansion. This is technologically challenging, and there are currently no commercial isothermal CAES implementations.

- Comparison of the Technologies

Table 1 summarizes the characteristics of the technologies that will be discussed in this document. Lithium ion batteries are included for comparison purposes only, as these batteries are currently not considered practical for long-duration storage.

Table 1. Comparison of Energy Storage Technologies

|

|

Max Power Rating (MW) |

Discharge Time |

Max Cycles or Lifetime |

Energy Density (watt-hour per liter) |

Round Trip Efficiency |

Levelized Cost of Storage (LCOS) |

Ref |

Company |

|

Li-ion Battery |

100 |

1 min – 8 hrs |

1,000 – 10,000 |

200 - 400 |

85 – 95% |

$285 - 518/MWh |

3 |

|

|

Pumped Hydro |

3,000 |

4 – 16 hrs |

30 – 60 years |

0.2 - 2 |

70 – 85% |

$152 - 198/MWh |

3 |

|

|

Compressed Air |

1,000 |

2 – 30 hrs |

20 – 40 years |

2 - 6 |

40 – 70% |

$0.12/kWh ($120/MWh) |

3 |

|

|

Hydrogen |

100 |

mins - week |

5 – 30 years |

600 (at 200bar) |

25 – 33%1 |

|

3 |

|

|

Liquid-Air Storage (LAES) |

|

4 hrs – 4 weeks |

|

|

<50% |

$100/MWh today $50/MWh in 10 yrs |

|

Highview Power |

|

Thermal Energy Storage – Siemens Gamesa |

|

2 Weeks (GWh) |

|

|

40 – 50% |

|

|

Siemens Gamesa |

|

Thermal Energy Storage – Stiesdal Storage |

|

12 hrs – 7 days |

|

|

|

$50/MWh |

6 |

Stiesdal Storage Technologies |

|

Aqueous Air Battery |

|

150 hrs |

|

|

50% |

|

7 |

Form Energy |

|

Advanced Compressed Air (A-CAES) |

|

|

|

|

|

|

|

Hydrostor |

|

Stacked Blocks |

80 |

|

30+ years |

|

85-90% |

$171 – 310/MWh |

8,9 |

Energy Vault |

1Reference [1] gives the round-trip efficiency of hydrogen as 25-45%. But when hydrogen is used to generate electricity via a modified natural-gas generation plant its efficiency is less. The Fourth Supplement to Danskammer’s Application to build a new gas-fired plant states that 5 TWh of curtailed wind used for electrolysis would generate an amount of hydrogen that would produce 1.7 TWh of electricity when burned in their turbines (based on their proprietary information). Using readily available data the amount of hydrogen produced by 5 TWh via electrolysis would generate 1.2 TWh of electricity when burned in a turbine.

Table 1. Comparison of Energy Storage Technologies (cont.)

|

|

Max Power Rating (MW) |

Discharge Time |

Max Cycles or Lifetime |

Energy Density (watt-hour per liter) |

Round Trip Efficiency |

Levelized Cost of Storage (LCOS) |

Ref |

Company |

|

Mountain Gravity Energy Storage |

|

150 hrs |

|

|

50% |

$50 – 100/MWh |

29 |

International Institute for Applied Systems Analysis |

|

Advanced Rail Energy Storage |

|

|

40+ years |

|

|

|

|

Advanced Rail Energy Storage |

|

Small Slope Pumped Storage Hydropower |

10 – 50 MW |

2-10 hrs |

|

|

|

|

|

RheEnergise |

|

Pumped Storage Hydropower using Submersible Pump Turbine |

|

|

|

|

|

|

|

Obermeyer Hydro, Inc. |

|

CO2 Battery by Energy Dome |

20 MW |

|

|

|

75 - 80% |

$50 – 60/MWh |

42 - 46 |

Energy Dome |

- Details About Each Technology

- Lithium Ion Batteries

Rechargeable batteries are generally considered to be insufficient for long-term power. Lithium-ion batteries currently dominate the energy storage market, but they are better suited for short-term storage because the charge they hold dissipates over time. Storing sufficient energy for months or years would require many batteries, which is too expensive to be a feasible option. [28]

For grid-level power, lithium-ion batteries present a long list of shortcomings: [4]

- Short-term storage: Most battery-based solutions store energy from one to four hours. Longer-lasting solutions (12+ hours) are not cost-effective.

- Limited battery life: Batteries last for a finite number of recharge cycles, and their life is shorter in cold weather use.

- Overheating risk: The risks are seen when operating temperatures are high, and when batteries are charged in freezing temperatures.

- Environmental concerns of lithium: Production of lithium batteries is energy intense with a high carbon footprint, and the disposal of such batteries is an environmental concern. Lithium at a large scale is associated with resource depletion, global warming, ecological toxicity, and human health impacts.

- Pumped Hydro [10]

Pumped hydro physically moves water from a low to a high reservoir. The water descends, when needed, to generate electricity. This is a well-known and utilized concept and still provides some 95 percent of U.S. grid storage, according to the U.S. Department of Energy.

|

Notional Diagram of Pumped Hydro |

Strengths:

- Once built, these systems boast a very low cost of storage.

- They hold massive amounts of energy compared to even the world’s biggest battery.

Weaknesses.

- These systems require mountains and reservoirs.

- It is extremely difficult to build new pumped-hydro storage plants, due to the permitting implications of large water-based infrastructure and recent difficulty in executing massive construction projects in general.

Examples:

- Blenheim-Gilboa Pumped Storage Power Station in upstate NY. This facility has a capacity of 1,134 MW and became operational in 1973.

- Compressed Air Energy Storage [11]

Compressed-air energy storage (CAES) plants operate by using motors to drive compressors, which compress air to be stored in suitable storage vessels. The energy stored in the compressed air can be released to drive an expander, which in turn drives a generator to produce electricity. A typical CAES system is shown in the following figure.

|

Compressed Air Energy Storage System by Apex [12] |

Strengths:

- Compared with other energy storage technologies, CAES plants have a very large power rating and storage capacity, low self-discharge, and a long lifetime.

Weaknesses.

- Conventional CAES plants have a relatively low roundtrip efficiency. However, research studies into more advanced CAES concepts, such as adiabatic and isothermal CAES, seek to improve this.

- They require large areas for storage. The examples below utilize large underground salt caverns as storage vessels. Such areas may not be readily available in NYS.

- Fossil fuel is used in the re-heating phase of the system.

Examples:

- A plant in Huntorf, Germany, with a rated generation capacity of 290 MW. Its storage area is 532,000 cubic meters (431.3 acre feet).

- A plant in McIntosh, Alabama, USA, with a generation capacity of 110 MW. Its storage area is 270,000 cubic meters (218.9 acre feet).

- Hydrogen [4, 5, 13]

Hydrogen energy storage is a form of chemical energy storage in which electrical power is used to produce hydrogen by the electrolysis of water. The hydrogen must then be stored, potentially in underground caverns for large-scale energy storage, although steel containers can be used for smaller scale storage. The energy is released by using the hydrogen as fuel in a combustion engine or a fuel cell. Hydrogen can be used as fuel for piston engines, gas turbines, or hydrogen fuel cells, the latter offering the best efficiency. Hydrogen energy storage is of interest because the gas forms the basis for the hydrogen economy in which it replaces fossil fuel in many combustion applications.

The widespread use of hydrogen in the global economy faces two important challenges: (1) the production of hydrogen from low-carbon sources is costly, and (2) the development of the hydrogen infrastructure is slow and holding back widespread adoption. Cost of building hydrogen distribution infrastructure and transport over large distances are major economic barriers to the implementation of hydrogen-based technologies. Additionally, large-scale central production will depend on market volumes to evolve in order to compensate for the capital expenditures of building up capacity. In future, carbon-neutral hydrogen could be produced by water electrolysis using electricity based on renewables. [43]

Hydrogen should not be combusted in a turbine to produce electricity. In addition to the very low round-trip efficiency when this is done (see Table 1 above), burning a gas/hydrogen blend would likely increase nitrous oxide emissions [47]. There are currently no commercially available power plants that can burn 100 percent hydrogen; existing turbine technology can handle between 5 and 30 percent hydrogen blended with gas.

The figure below shows the flow of hydrogen from production to storage to end use.

|

Hydrogen from Production to Storage to End Use [4] |

Strengths

- Hydrogen can replace fossil fuel in many combustion applications where electrification may not be practical; it can be used as fuel for fuel cell cars or as feedstock for the chemical and petrochemical industry.

- Potential for interseasonal storage

Weaknesses

- Very low round trip efficiency

- Need for underground caverns as storage. These would need to be co-located with large wind and solar installations in order to capture the curtailed wind or solar.

- Need to develop substantial hydrogen infrastructure.

- Should not be used to generate electricity by being combusted in a turbine.

Examples

- 5 MW PEM electrolyzer by Cummins for Douglas County Public Utility District in Washington state. This electrolyzer will be dedicated to producing hydrogen from renewable energy. Expected to be operational in 2021.

- 20 MW PEM electrolysis plant by Cummins in Becancour, Canada for Air Liquide. Planned to be operational sometime in 2021.

- 1.2 MW PEM electrolysis plant by Cummins established in Denmark in 2018.

- Liquid-Air Energy Storage [14, 15]

Highview Power is a UK startup developing an energy storage system that uses liquid-air technology (LAES). In this technology electricity is used to cool air down to -196°C, shrinking its volume by a factor of 700. This frozen liquid air is then stored in low-pressure vacuum-insulated steel tanks — the kind that house liquefied natural gas. When this cryogenically frozen air is exposed to ambient temperatures, it turns back into a gas and rapidly expands, with the rush of air from this 700-fold expansion directly driving an electricity-generating turbine.

Strengths

- This is a long-duration energy storage solution available today that is locatable and can offer multiple gigawatt-hours of storage (i.e., weeks’ worth of storage, not just hours or days).

- Relies on low-risk, proven technology, generates zero emissions, has zero water impact.

- Can be delivered at a cost of approximately half the current cost of traditional lithium-ion batteries.

Weaknesses [22]

- Low round trip efficiency, probably under 50%, which is much lower than that of batteries and pumped hydro.

- LAES is only practical on a relatively large scale.

Examples

- U.S. project (50 MW, 400 MWh) in northern Vermont by Highview Power, construction begun 2021

- U.K. project (50 MW), in Carrington, Northern England, by Highview Power, construction begun 2021

- Pilsworth Grid Scale Demonstrator Plant, Bury, Greater Manchester, England.

|

Highview Plant in Northern Vermont |

- Thermal Energy Storage by Siemens Gamesa [16, 17, 17a]

In a thermal energy storage (TES) system, energy is stored as heat in some form of medium for future use. There are three main types of TES systems: sensible heat storage, latent energy storage, and thermal-chemical storage. Compared to the other options, sensible heat storage is relatively inexpensive and much less complicated; it is also the only option to have significant commercial availability in the power sector. Latent energy storage and thermal-chemical storage systems are expensive and as of now are largely experimental.

In a sensible heat TES system, a liquid or solid storage medium—such as water, molten salts, sand, or rocks—is heated or cooled to store energy. One such system has been developed by Siemens Gamesa, and construction of a pilot plant in Hamburg, Germany, is underway.

|

Demonstrator with 30 MWh storage capacity and 5.4 MW resistive heater in Hamburg |

This plant would convert electrical energy into hot air using a resistance heater and a blower to heat about 1,000 tonnes of volcanic rock to 750°C. When required, the facility would convert the stored thermal energy back into electricity using a steam turbine. Due to efficient insulation, the heat can be stored for a week or longer — at a fraction of the costs of battery storage. Siemens Gamesa says the pilot plant can store up to 130 MWh for a week.

Strengths [18]

- The time required to design and build a TES facility is shortened because the system relies on conventional technology and uses components that are already widely used in the power and processing industries – such as turbines, compressors, heat exchangers, and electrical generators.

- All of the options for medium (the substance that absorbs the heat in the tank) are environmentally friendly – chemical and toxin-free.

- The medium that fills the storage tank consists of materials that are abundant and inexpensive – such as molten salts, water, or gravel.

- A facility can be installed anywhere in the world, regardless of geography.

- It can be scaled up or down to meet the location’s grid storage needs.

- The technology can store more energy in a given volume (has a higher energy density) than pumped hydro dams.

- Uses off-the-shelf equipment that does not degrade in any way – unlike lithium-ion batteries. The components have a long lifetime – they last for decades before needing to be replaced.

Weaknesses

- Technology not yet completely proven or commercialized.

Examples

- Siemens Gamesa’s first commercial projects of up to 500 MWh in 2022

- Thermal Energy Storage by Stiesdal Storage [19]

The GridScale energy storage system by Stiesdal Storage Technologies is a pumped thermal energy storage system that uses crushed basalt rock (which is abundant and low-cost) as a storage medium. The technology heats up pea-sized crushed stones in insulated steel tanks using an innovative pump-based system and releases the stored energy via a turbine to produce electricity. It has undergone tests at the Technical University of Denmark (DTU), but will now be trialled at a solar array in the Zealand region on the Baltic Sea, as well being incorporated in a Danish Energy Agency ‘GridScale’ project.

The system’s main components are a turboexpander unit with pre-pressure compressor, controls etc., a filter unit with air filters and manifolds, and two rows of standardized storage reservoirs. The storage duration is adjusted with the number of storage tanks. Power rating is adjusted with the number of parallel units.

The GridScale range covers both the 12-18 h duration required for day-to-day smoothing of solar PV, and the 3 to 7 days duration required for smoothing of wind power over gaps caused by low wind periods..

|

The GridScale energy storage plant, consisting of an adjustable number of storage tanks and the GridScale-specific charge-discharge system. |

GridScale is built for modular adaptation to local demands. The storage duration is adjusted with the number of storage tanks. |

Strengths

- A facility can be installed anywhere in the world, regardless of geography.

- It can be scaled up or down to meet the location’s grid storage needs.

- The medium that fills the storage tank (crushed basalt rock) is abundant and inexpensive.

- The GridScale range covers both the 12-18 h duration required for day-to-day smoothing of solar PV, and the 3 to 7 days duration required for smoothing of wind power over gaps caused by low wind periods..

- Stone can store large volumes of energy in a relatively small space, and it can withstand innumerable rounds of charging and discharging of the storage.

- The facilities can be placed at solar farms and offshore wind farms, at substations and industrial facilities, and perhaps on the future wind energy islands.

Weaknesses

- Technology not yet completely proven or commercialized

Examples

- Trial project solar array in the Zealand region on the Baltic Sea (April 2021)

- Trial project for Danish Energy Agency

- Aqueous Air Storage [20, 21]

Last year an agreement was announced between Form Energy, a long-duration energy storage startup funded by Bill Gates’ Breakthrough Energy Ventures and other investors, and Green River Energy in Minnesota for the installation of a 1 MW/150 MWh “aqueous air battery” to be installed and operational in 2023. Unfortunately not much is known about Form Energy’s product. Press releases say only that it “leverages some of the safest, cheapest, most abundant materials on the planet”. In a 2019 interview a professor of materials science working at the company hinted about the chemistry of the new batteries: “We’re looking for batteries that can use either metals or other elements that are much lower cost [compared to lithium, nickel, cobalt, iron, manganese, all of which are used in lithium-ion batteries], and an example of that would be sulfur.” The implication is that this new battery system can be fueled by sulphur and water.

A research paper published in 2017 describes an “air-breathing aqueous sulfur flow battery” that can provide 100+ hours of energy storage. [40]

Strengths

- Cheaper than lithium-ion batteries

- Does not require metals and elements that have high environmental impacts, i.e., resource depletion, global warming, ecological toxicity, and human health impacts.

Weaknesses

- Power output is low.

Examples

- Form Energy’s first commercial project is a 1 MW, grid-connected storage system capable of delivering its rated power continuously for 150 hours with Minnesota-based utility Great River Energy. [30] The system is expected to be deployed before 2023.

- Advanced CAES [22, 23]

Advanced Compressed Air Energy Storage (A-CAES) is a technology developed by Hydrostor, a company based in Toronto, Canada. In this technology there are 4 steps. (1) Renewable energy is used to run a compressor and produce heated compressed air. (2) Heat is extracted from the air stream and stored inside a proprietary thermal store, preserving the energy for use later in the cycle. (3) The compressed air is stored in a purpose-built cavern where hydrostatic compensation is used to maintain the system at a constant pressure during operation. (4) Hydrostatic pressure forces air to the surface where it is recombined with the stored heat and expanded through a turbine to generate electricity on demand.

|

|

Strengths

- Lowest installed cost per kWh for large-scale, long-duration energy storage (100+ MW)

- 50+ year system life, with no replacements required and nearly unlimited cycling

- Low operating costs, and increased efficiency over traditional CAES systems

- Proprietary purpose-built air caverns allow for flexible project siting

- No toxic material, contaminants, or thermal impacts on environment; suitable for urban settings

- Uses well-proven mechanical equipment from Tier 1 OEM suppliers and proven construction techniques

- Adiabatic thermal storage system uses no fossil fuels and results in no emissions

Weaknesses

- Technology not yet fully commercialized.

Examples

- Goderich A-CAES Facility in Goderich, Ontario, Canada is the world’s first commercially contracted Advanced-CAES facility.

- Toronto Island Demonstration Facility developed in 2015 with utility host Toronto Hydro. This is the world’s first grid-connected adiabatic CAES facility.

- 13 projects by Hydrostor in the pipeline in US, Canada and Australia.

- Stacked Blocks [24, 25, 26, 27]

The stacked block storage developed by Energy Vault is an electricity storage battery consisting of blocks of concrete that weigh 35 tons each and a six-arm crane with a novel design. These “bricks” are stacked one on top of the other in the shape of a tower, like pieces of Lego, to store up power when there is surplus production of electricity from wind turbines and solar panels. The bricks are unloaded again, using the force of gravity to produce electricity, when other power sources are absent. The loading and unloading operations are controlled by a software program which is able to adjust for any swaying of the blocks in high winds.

The battery is based on principles that have already been applied for decades at hydro power stations using a pump system which exploits the altitude difference between two reservoirs. This solution by Energy Vault replaces the water with custom made composite blocks which are made using industrial waste materials, including materials diverted from landfills.

This system is modular and flexible; plant capability ranges from 20-35-80 MWh of storage capacity and a 4-8MW discharge of continuous power for 8-16 hours.

Strengths

- Round-trip efficiency of 85%

- A plant can operate for 30 years with little maintenance and almost no fade in capacity.

- The concrete blocks are constructed with waste materials.

Weaknesses

- Energy Vault’s concrete blocks will have to be built on-site, and each 35 MWh system would need a circular piece of land about 100 meters (300 feet, i.e., the size of a football field) in diameter. Batteries need a fraction of that space to store the same amount of energy. But there’s a niche for such plants in places that have abundant access to land and building material.

- A number of shortcomings are described in [27]. They include the carbon footprint from producing the steel and concrete necessary to build the plant, the effect of wind on the crane lifting the blocks, and other weaknesses of the system.

Examples:

- Commercial Demonstration Unit, Ticino, Switzerland

- Tata Power 35 MW, somewhere in Italy, operational by 2019. No indications that it is up and running yet.

|

Notional Diagram of Stacked Blocks |

Commercial Demonstration Unit, Switzerland [24] |

|

|

|

- Mountain Gravity Energy Storage [28, 29, 30]

Mountain Gravity Energy Storage (MGES) is a gravity-based concept, similar to pumped hydro and stacked blocks. This system is proposed by Julian Hunt, an engineering scientist at the International Institute for Applied Systems Analysis in Austria, and his team. This system uses an electric motor to lift a solid mass to a high elevation in the charging mode; it then releases that mass to rotate the electricity generator whenever needed (i.e., discharging). The technology is already mature and applied in different applications such as in the construction, recreational sites, and mining industries. The difference is that the motor in MGES also generates electricity when lowering the elevation of the mass. The media for energy storage can be either sand or gravel or similar material resting on the top of a mountain, which allows the system to store energy in long-term cycles, even in a yearly scale. MGES cost varies from $50 -100/MWh of stored energy and $1–2 M/MW of installed capacity.

|

Diagram of Mountain Gravity Energy Storage |

Strengths

- A feasible option for micro-grids, for example, small islands and isolated areas, and power systems where electricity costs are high, demand for energy storage is smaller than 20 MW, and there are monthly or seasonal storage requirements.

- Can provide seasonal storage in locations where there is no water for pumped storage solutions.

Weaknesses

- Less suitable for systems with large storage needs (i.e., greater than 20 MW)

- Requires mountains; smaller height difference results in smaller storage capacity.

Examples

- None. For now this is a novel and interesting concept that hasn’t quite reach fruition.

- Advanced Rail Energy Storage [32]

This system by Advanced Rail Energy Storage (ARES) is another storage system that uses the potential mechanical energy due to gravity. This system requires a slope with rail tracks that transport heavily loaded cars up and down the slope. Electricity from the grid powers the cars up the slope; then the cars can be lowered down the slope to generate electricity for the grid. The layout of this system at the company’s demonstration plant in Nevada is shown below.

|

Overview of Tracks and Cars at Nevada Site |

|

Mass Cars Descending (i.e., Generating Electricity) |

The figures below show the steps in storing and discharging electricity. First, electricity from the gird is used to power a highly efficient electric motor that lifts a heavy mass car uphill. At the top of the slope the car rests, holding potential energy. In the final step electricity is generated as the mass car is lowered, turning the reversible motor backwards and acting as a generator of power.

|

Step 1: Electricity is pulled from the grid to turn a highly efficient electric motor lifting a heavy mass car uphill. |

Step 2: The mass car at maximum elevation resulting in maximum potential energy. |

|

Step 3: Electricity is reproduced as the mass car is lowered, turning the reversible motor backwards and acting as a generator of power. |

Strengths

- Uses no fossil fuel or water.

- Produces zero emissions or hazardous waste.

- Has a 40+ year service life with no degradation or thermal runaway.

Weaknesses

- Requires a very large land area.

Examples

- 50 MW plant in Nevada

- Small Slope Pumped Storage Hydropower [33]

A UK company, RheEnergise, has created a pumped-hydro energy storage system which it is calling High-Density Hydro. The RheEnergise systems could operate across smaller elevation changes than conventional hydro power systems.

Like conventional pumped hydro, the system would use excess energy – such as that generated by wind turbines on a windy day with low demand – to pump the liquid uphill from underground storage tanks. After travelling uphill through underground pipes, the liquid would then be released to power downhill turbines when electricity demand is higher.

The High-Density Hydro system uses dense liquid instead of water. The fluid is two-and-a-half-times denser than water, and could therefore potentially provide two-and-a-half-times the power of equivalent conventional systems. The liquid is a fine-milled suspended solid in water, with low viscosity and low abrasion characteristics. The base material is used in oral medication applications, in a similar way that chalk is used as a bulking agent for pills and tablets. The raw materials are common and available, including in the UK, and the fluid could either be manufactured on-site or at a depot.

RheEnergise projects provide 10MW to 50MW power and 2 to 10 hours of storage capacity.

|

High-Density Hydro: Energy Storage by RheEnergize |

Strengths

- Projects can be installed on hills 2.5x lower than a project using water and still achieve the same power - for example, there are so many more hills at 150m than at 375m.

- Compared to conventional pumped-hydro storage a project will be 2.5x smaller, by volume, meaning dramatically lower construction costs, faster build times, easier reinstatement and easier landscaping - projects can be entirely hidden.

- Zero emissions during operation.

- Very few end-of-life liabilities

Weaknesses

- Relatively low power.

- This is medium-duration storage rather than long-duration; so far the technology has a maximum storage capacity of 10 hours.

Examples

- Not known at this time.

- Pumped-storage hydropower (PSH) using new design submersible pump turbine in a vertical “well” [34, 35, 36]

Obermeyer Hydro, Inc., has been awarded $1.18 million to to develop an advanced closed-loop PSH configuration as part of the U.S. Department of Energy Water Power Technologies Office’s HydroNEXT initiative. Obermeyer is aiming to design a cost-effective, highly flexible PSH system that reduces project costs, shortens deployment timelines, and is optimized for U.S. energy storage requirements. A diagram of the new pump turbine can be seen on the company’s website.

The company’s configuration is designed to only require construction of a vertical shaft to position a submersible pump-turbine/motor-generator sufficiently deep, instead of an elaborate underground cavern that would involve much larger excavation. Simplified construction and reduced installation costs make such an installation practical at sites that up to now would not have been feasible. The simple underground structure may be constructed under a wide range of geological conditions.

Strengths

- 45% savings in construction costs as compared to conventional PSH systems

- Submersible machines are compact and factory assembled and tested, reducing on-site work and construction costs.

- Energy storage within the power converter equipment provides virtual instantaneous transition between supplying and absorbing energy from the grid.

- Geologic risk and constraints are reduced, opening more potential sites such as non-powered dams to economical development.

Weaknesses

- Small storage capacity

Examples

- None currently; system still in design stage.

- CO2 Battery by Energy Dome [42 – 46]

Though Energy Dome calls it a “battery”, it is really a system that stores energy by changing the state of carbon dioxide, CO2, in a closed loop. It is marketed as a long duration and large-scale energy storage system based on a thermodynamic process. It is not a true thermal energy storage (TES) system in that the energy is not stored as heat, although a TES is used.

The principal element of the system is CO2, which is stored in a large, closed container, called a Dome. To “charge” the system, the CO2 is pumped from the Dome and compressed. The heat from this compression is stored in a TES and used to convert the CO2 gas to a liquid, which is stored in tanks.

To discharge, the liquid CO2 is released from the storage tanks, causing it to convert back to a gas and expand. It then passes back through the TES, where it is heated causing further expansion. The pressure from the expanded CO2 powers a turbine, generating electricity. After passing through the turbine, the CO2 is pumped back into the Dome, ready to begin the process again.

Since it is a closed system, there is no CO2 going into the atmosphere.

The first CO2 battery facility is now fully operational in Sardinia, Italy.

Strengths

- Uses off the shelf equipment available now.

- Has a cost advantage over batteries, with an estimated LCOS of $50-60/MWh.

- Lower environmental impact than batteries. Can be built using available recycled materials.

- Can be installed anywhere as long as there is ready availability to the grid.

Weaknesses

- Not as efficient as batteries. However, its 75% to 80% efficiency is greater than other long-duration energy storage technology currently on the market.

- It has a large footprint, especially for a relatively low power rating, so the area needed for the Dome and other structures may be a limiting feature.

Examples

- A 4MWh piolet system is in currently in operation. A full-scale 20 MW/200 MWh commercial plant is scheduled to be deployed by the end of 2023.

- Other New Technologies

The technologies described below are not considered long-duration storage because their discharge time is less than 4 hours. However, they could be useful replacements for lithium-ion batteries without the negative environmental effects.

Gravity-Driven Energy Storage System by Gravitricity [31]

This system by Scotland-based Gravitricity works by raising weights as heavy as 12,000 tons into a lattice tower and releasing them into a deep shaft to discharge energy as required. A 250kW prototype of the concept is currently (August 2020) being built. The prototype will use two 25-tonnes weights suspended by steel cables. The two-month trials, which will be carried out with the system grid-connected, are expected to lead to development of a first full-scale 4MW model later in 2021. The system is expected to provide 4 MW of power for a duration of 15 minutes. The company sees the technology being deployed in repurposed mineshafts around the world.

This technology is not long-duration storage but is intended more as a replacement for lithium-ion batteries at a much lower LCOS.

|

Above-ground part of Gravitricity’s gravity-based energy storage system. Photo by Gravitricity |

Advanced Flywheel Storage [37, 38]

A flywheel is a rotating mechanical device that is used to store rotational energy that can be called up instantaneously. A flywheel battery stores electric energy by converting it into kinetic energy using a motor to spin a rotor. The motor also works as a generator; the kinetic energy can be converted back to electric energy when needed.

|

|

In the late 1990s and 2000s, flywheels were used mostly for short-term energy storage, providing five-to-ten-minute backup power in data centers, for example. But Ben Jawdat, the founder and CEO of Revterra, a flywheel startup based in Texas, thinks that his company has overcome the shortcomings, making flywheels capable of long-term energy storage for renewable energy.

The most important technological development in Revterra’s system is in the bearing. Previous flywheel storage systems used either mechanical bearings, such as ball bearings, where the bearing physically touches the rotor, or active magnetic bearings, which eliminate friction at the cost of complex and power-hungry control systems. Both of those options ultimately result in a significant amount of the rotor’s mechanical energy being lost as waste heat.

Revterra uses passive magnetic bearings that can hold a rotor in equilibrium without an external control that consumes the additional energy, thus improving the energy efficiency even further by removing the energy consumption of the bearing itself. Revterra’s 100 kWh flywheel system will lose only 50 Watts when idling. In comparison, many flywheels consume over 1000 Watts, according to Jawdat. So if you charge the flywheel battery all the way and discharge completely, you would only lose about 10% of the energy, he adds.

Compared to lithium-ion batteries, flywheel batteries essentially last forever. “You can charge and discharge all day every day for 30 years, and your [flywheel] battery will still have 100% capacity,” Jawdat says. “With chemical batteries, you have to keep replacing them every five to ten years,” which drives up the cost for long-term usage. Revterra has built and tested a working prototype 1 kW flywheel system; the company is currently working on a commercial scale 100 kWh system.

Strengths

- Round-trip efficiency of 90%

- Durable and long-lasting

Weaknesses

- Very low power: commercial scale system under development will have only 100 kWh.

Examples

- Working prototype of a 1 kW system

- Development of a commercial scale 100 kWh system is ongoing.

- Conclusions

- There is no one perfect solution. Some of the more advanced concepts have many advantages but have not been yet fully proven or commercialized.

- Long-duration storage should be an essential part of large-scale wind and solar installations. Wind and solar power that needs to be curtailed must have energy storage available. Provision for on-site storage should be part of these large-scale projects.

- The Climate Leadership and Community Protection Act (CLCPA) passed in 2019 should be modified to specify amount of long-duration storage that is needed. CLCPA specifies 3,000 MW of energy storage by 2030, but does not specifically address long-duration storage. Battery storage by itself is not sufficient.

- There should be an incentive and financing program for long-duration storage. Instead of (or perhaps in addition to) the Parker/Cusick bill (S3281/A3788) to subsidize hydrogen, there should be a comparable bill to subsidize long-duration storage.

References

[1] Energy Storage 101: Applications | Woodlawn Associates

[2] Grid-Scale Battery Storage: Frequently Asked Questions (nrel.gov)

[2a] Adiabatic Process - an overview | ScienceDirect Topics

[2b] Isothermal Compressed Air Energy Storage | Energy Storage Association

[3] Fact Sheet | Energy Storage (2019) | White Papers | EESI

[4] Optimizing Renewable Energy Storage With Hydrogen Fuel Cells (ballard.com)

[5] Hydrogen Energy Storage - an overview | ScienceDirect Topics

[6] Email from Stiesdal Storage Technologies, May xx, 2021.

[9] Revolutionary idea to store green power for the grid - SWI swissinfo.ch

[10] The 5 Most Promising Long-Duration Storage Technologies Left Standing | Greentech Media , September 24, 2020

[11] Compressed Air Energy Storage - an overview | ScienceDirect Topics

[12] Technology Overview | APEX CAES

[13] Three Cummins hydrogen production facilities that are helping build a green economy | Cummins Inc.

[13a] The Use of Hydrogen as an Energy Storage System (fuelcellstore.com)

[15a] Plants | Highview Power

[16] Siemens Gamesa launches revolutionary thermal storage pilot | Recharge (rechargenews.com)

[17] The Advantages Of Using Heat To Store Renewable Energy (intelligentliving.co)

[17a] Thermal energy storage with ETES I Siemens Gamesa

[18] Hot rocks offer solution to grid-scale energy storage The Engineer

[19] The GridScale technology explained | Stiesdal

[21] Will Form Energy Aqueous Air Battery Challenge Tesla For Grid Storage Dominance? (cleantechnica.com)

[22] Canadian startup Hydrostor is storing energy in compressed air — Quartz (qz.com)

[24] COMMERCIAL DEMONSTRATION UNIT - Energy Vault

[26] Revolutionary idea to store green power for the grid - SWI swissinfo.ch

[28] Mix Mountains and Gravity for Long-Term Energy Storage - IEEE Spectrum

[30] Revised manuscript 11.11.19.pdf (iiasa.ac.at)

[32] https://aresnorthamerica.com/our-company/

[34] https://www.nrel.gov/news/program/2020/psh-ensures-resilient-energy-future.html

[36] Pumped Storage | Obermeyer Hydro, Inc.

[37] Mechanical Electricity Storage Technology | Energy Storage Association

[38] Flywheels Turn Superconducting to Reinvigorate Grid Storage Potential - IEEE Spectrum

[39] Long-duration storage can help clean up the electricity grid, but only if it's super cheap

[43] Will Locket and CO2 Battery

[44] Energy Dome

[45] Recharge Article

[46] Short Video Explaining The Process

[47] Hydrogen: Future of Clean Energy or a False Solution? | Sierra Club

Concerns about Holtec's Plan for Decommissioning Indian Point

Holtec Plan for Decommissioning Indian Point

The deadline to submit comments to the NRC on Holtec’s "Indian Point Energy Center Post Shutdown Decommissioning Activities Report" is over but we still need to advocate for policies that will lead to safer decommissioning and get federal representatives to provide robust oversight of the NRC with regard to this and future decommissioning projects.

OUR CONCERN IN A NUTSHELL: Holtec’s Plan (“PSDAR”) gives woefully inadequate or non-existent treatment to key safety and financial issues affecting the New York Metropolitan Area.

Problems with Holtec’s planned spent fuel handling and dry storage systems include:

Cask and Canister issues: 20 - 25 year warranty on canisters and cask system

● 10 mRem limit in Joint Proposal should be honored (RW), as opposed to 25mRem required by NRC

● Visual inspection of canisters is not adequate (see below under monitoring). There are no pressure monitors or relief values to assess and protect canister integrity. The Nuclear Waste Technical Review Board.recommends that Spent Nuclear Fuel (SNF) and its containment must be maintained, monitored, and retrievable in a manner that prevents radioactive leaks and hydrogen gas explosion.

● Holtec plans to continue to use a containment system for Spent Nuclear Fuel (SNF) of thin-walled canisters (½” -- ⅝”) inside thicker concrete casks lined up like bowling pins on a concrete tarmac -- a configuration which is more vulnerable to terrorism than Hardened Onsite Storage (HOSS), which could be much safer and should be explored. In Europe and many other countries nuclear waste is stored in more robust canister systems (10” - 20” thick) and often in hardened buildings.

High Burnup Fuel: About 60% of Indian Point’s spent fuel inventory is high-burnup (HBU) fuel, which is much hotter and more radioactive than ordinary spent fuel, and requires at least seven years or more before moving it to dry cask storage. Holtec’s plan to compress this process to three years or less may reduce costs, but also puts workers and the surrounding community in jeopardy.

Inadequate Site Remediation: Holtec’s preliminary Post Activities Shutdown Report (PSDAR) indicates that it will do nothing to remediate radiological contamination known to be leaking into the groundwater and the Hudson River, and that it will only superficially remediate contaminated soils,

Radiation Monitoring: Holtec’s Post shutdown plan makes no provision for effective, accurate, off-site radiation monitoring despite the fact that radioactive particles and gasses are expected to be released into the air during the demolition of structures on site. The NRC has no requirement for offsite monitoring and therefore absolves Holtec from paying for it. There is also no plan to detect increasing pressure or temperature, container crack formation, or other problems that can lead to radiation leakage from the sealed thin-walled canisters they plan to use -- nor any way to respond to and remediate a leak or other failure, should it occur.

● Perimeter monitoring is not adequate to capture issues directly at the work site which can impact the workers.

● Offsite monitoring is needed, especially at nearby elementary school.

● At Bruce Units 1 & 2 in Ontario, Canada more than 500 workers were exposed to radioactive dust and volatilized isotopes while cutting channel tubes that needed to be replaced.

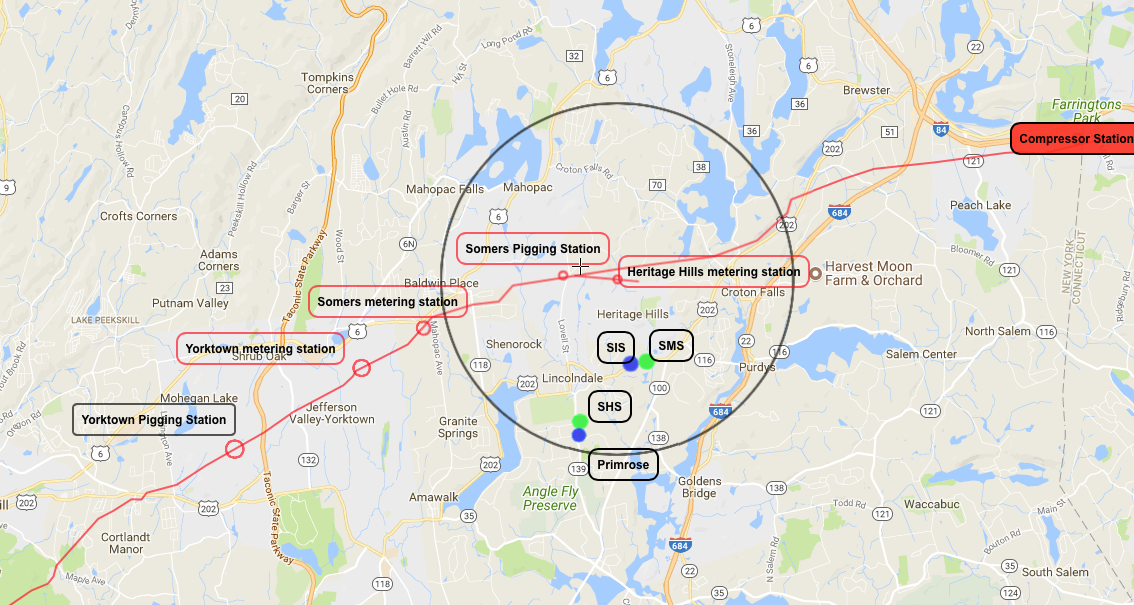

Pipeline Risks: Indian Point is not only located at the intersection of two earthquake faults, it is also unique in that it has the Algonquin and a new 42” high-pressure AIM gas pipelines running under and adjacent to the facility. No other nuclear site in the nation is so threatened by pipelines. Demolition work inherent to decommissioning elevates the hazard. NYS and multiple independent experts recognize the risk. However, the pipelines are not even mentioned in Holtec’s PSDAR. The NRC’s Office of Inspector General (OIG) harshly criticized the NRC staff for dismissing the danger of an explosion as “not credible, and instead ignoring key data and tailoring its modeling of explosion risks to fit the desired foregone conclusion that no action is necessary.

Earthquake Zones should be studied further to have a full picture of the environment in which the decommissioning will take place. Request information from Columbia University Lamont Dougherty Earth Observatory (LDEO)

● North Anna: Dominion is seeking a license to build a new plant, despite the Aug. 23 earthquake at North Anna 1 & 2, which didn’t meet seismic standards -- but they are now designing Unit 3 to do so. Units 1 & 2 are still operating

● Information on two earthquake zones has been scrubbed from record (Paul G., please elaborate)

Emergency Planning and Response: In the Joint Proposal, NYSDHSES will oversee Emergency Management and Response, with funding provided by Holtec, starting at $1,000,000 per reactor in 2022, decreasing when all the radioactive fuel is move to dry cask storage and then dropping to $250,00 -- $750,000 depending on when that transfer is completed, and to $100,000 after Partial Site Release and as low as $25,000 until License Termination. Although dangers resulting from failure of a reactor, steam turbines, transformer explosions or other major failures have decreased since the plant ceased operation, nearly 2,000 tons of highly radioactive fuel is stored on site and dismantling the facility poses new dangers and the need for emergency planning will continue as long as waste is stored on site. The funding schedule is clear but not the actual emergency evacuation plan for various occurrences.

● Oyster Creek has a transfer pit, but no onsite overpack. It will take many hours or days to get one transported from Camden to Lacey Township and it is questionable whether this is an effective solution or whether a very expensive hot cell is needed.

Transportation: Holtec’s plan envisions shipping Indian Point’s radioactive waste, including highly radioactive spent fuel, down the Hudson River by barge.

● Barging contaminated materials down the Hudson River through NY Harbor poses a risk to river towns and the greater NYC Metropolitan area.

● As the high-level nuclear waste is transported across the country, it will threaten the safety of communities along the transport routes, especially EJ populations in under-represented cities and rural areas.

● A 2019 Department of Energy (DOE) Gap Analysis indicates that more needs to be understood about the impact of changing the vertical orientation used in dry cask storage to a horizontal orientation for transport, including increased temperature and possibility of degrading the cladding which hold the fuel pellets in place in the fuel road. It recommended additional modelling, which is not being done.

● Aging infrastructure along transportation routes -- road, bridges, overpasses, and tunnels -- has not been assessed to see if it is capable of handling 120,000 metric tons of nuclear waste that would be sent to proposed Consolidated “Interim” Storage (CIS) in Texas or New Mexico -- let alone preparing for effective emergency response should an accident occur due to failed infrastructure and/or other causes. Note: Interim is in quotes because, if allowed, it could well become indefinite, if not permanent.

Environmental Justice Concerns: The operation and decommissioning of nuclear power plants, transportation and storage of spent nuclear fuel disproportionately impacts communities of color and low income in reactor communities, such as those at and surrounding Indian Point, those transportation routes, and especially indigenous and Latinx communities at potential recipient communities in TX and NM.

● Leona Morgan, Dine activist, gave a compelling overview of the long history of harmful impacts to the Downwinders from the Trinity Atomic test site, uranium mining, milling, processing, transportation and now storage. These communities -- mainly indigenous and Latinx -- have been burdened with radiation exposure and have suffered health and other impacts and should not be forced to host most of the 3,200 spent fuel canisters -- the nuclear waste from nearly 100 reactors across the nation.

● The proposed CIS facilities are collocated in areas of fossil fuel extraction -- including active oil fields and hydraulic fracking sites, which can induce earthquakes.

● Holtec’s plans for off-site transport of radioactive waste, shipping Indian Point’s spent fuel to New Mexico to be stored at Holtec’s consolidated interim storage facility are unacceptably dangerous, and violate the principles of environmental justice and consent-based siting, as well as federal law, which prohibits interim storage before a permanent repository is sited.

Because transportation is so dangerous and the proposed CIS storage is both unjust and unlawful, we must be very certain that onsite storage is done as safely as possible.

Pressing need for Nuclear Harvesting and Autopsy, especially to inform License Extension Applications: Reactor owners are now seeking 40 - 60 - 80 year license extensions, but little to nothing has been learned about effects of operations on aging. Indian Point can serve as a pilot to design an engineered testing system to send samples for autopsy. We need regulations requiring autopsy of closing reactors so that lawmakers and the NRC and other regulatory bodies will have information on which to base future decisions, especially in the face of so many license extension applications. The Seattle Times will publish an article on this in Sept.

Financial Risk to New Yorkers: With the License Transfer, Holtec has taken over the $2.3 billion plus Decommissioning Trust Fund. While NYS has negotiated some important financial assurances, Holtec is a privately owned company with no financial transparency. Ultimately, if everything does not go according to Holtec’s Plan, New York taxpayers may be left holding the bag.

NRC Oversight: Given its history of easily granting waivers and exemptions to the nuclear industry, often at the expense of public health and safety, and of at times not following its own regulations, the NRC has been described as an “industry-captured agency”.

● Frank von Hippel, former assistant director for national security in the White House Office of Science and Technology, recently wrote, “Over the past two decades, the NRC has been captured by the nuclear power companies it is supposed to regulate. The process of capture and resulting erosion of regulation has been driven in part by the increasingly poor economics of nuclear energy as companies struggle to avoid large costs due to additional safety measures. However, the path has been laid to a potential disaster.”

● NRC ignores or dismisses many of the problems cited above. It has allowed Holtec to make unauthorized and flawed design changes stand, has exempted Spent Nuclear Fuel (SNG) containment from meeting American Society of Mechanical Engineers Standard (ASME) Standards, ignored NWTRB recommendations, and made other decisions that compromise their role as regulators and could have severe consequences.

● This is a chance for the NRC to honor its mission by putting people before industry profit and making wise decisions that include planning for worst case scenarios, rather than dismissing those as “not credible.”

Risk Assessment Shows Dangers of AIM gas pipelines near Indian Point

On June 22, 2018, several NYS agencies jointly released a letter to FERC outlining actions that need to be taken to keep our area safer from the threat of catastrophe due to the location of the AIM gas pipelines close to Indian Point nuclear facilty. Accompanying the letter was the Exectuve Summary of the risk assessment on which the recommendations were based. The extreme danger we are in has been confirmed.

The agencies made the following recommendations:

- "FERC should not allow any additional natural gas capacity on the Algonquin pipelines...

- "FERC should require regular testing of Enbridge’s ability to remotely close valves

on the 42-inch, 30-inch, and 26-inch pipelines in the vicinity of Indian Point within

three minutes of an event... - "FERC must work with NRC to coordinate a review of Indian Point-owner Entergy

Corp.’s decommissioning plan when filed to determine potential impacts to the

original Algonquin pipelines and the AIM pipeline...

pipelines.

"The Agencies also called on FERC to re-evaluate whether the NRC and Entergy

analyses relied on by FERC during the review of the AIM project were sufficient. The

NRC and Entergy analyses concluded that the Indian Point reactors could safely shut

down if there were a pipeline incident, but they may not have fully considered all

necessary and appropriate factors, including for example the different design

characteristics of the buildings housing the spent nuclear fuel cooling pools."

Read the press release: here.

Read the letter from the agencies to FERC: here.

Read the Executive Summary of the risk assessment: here.

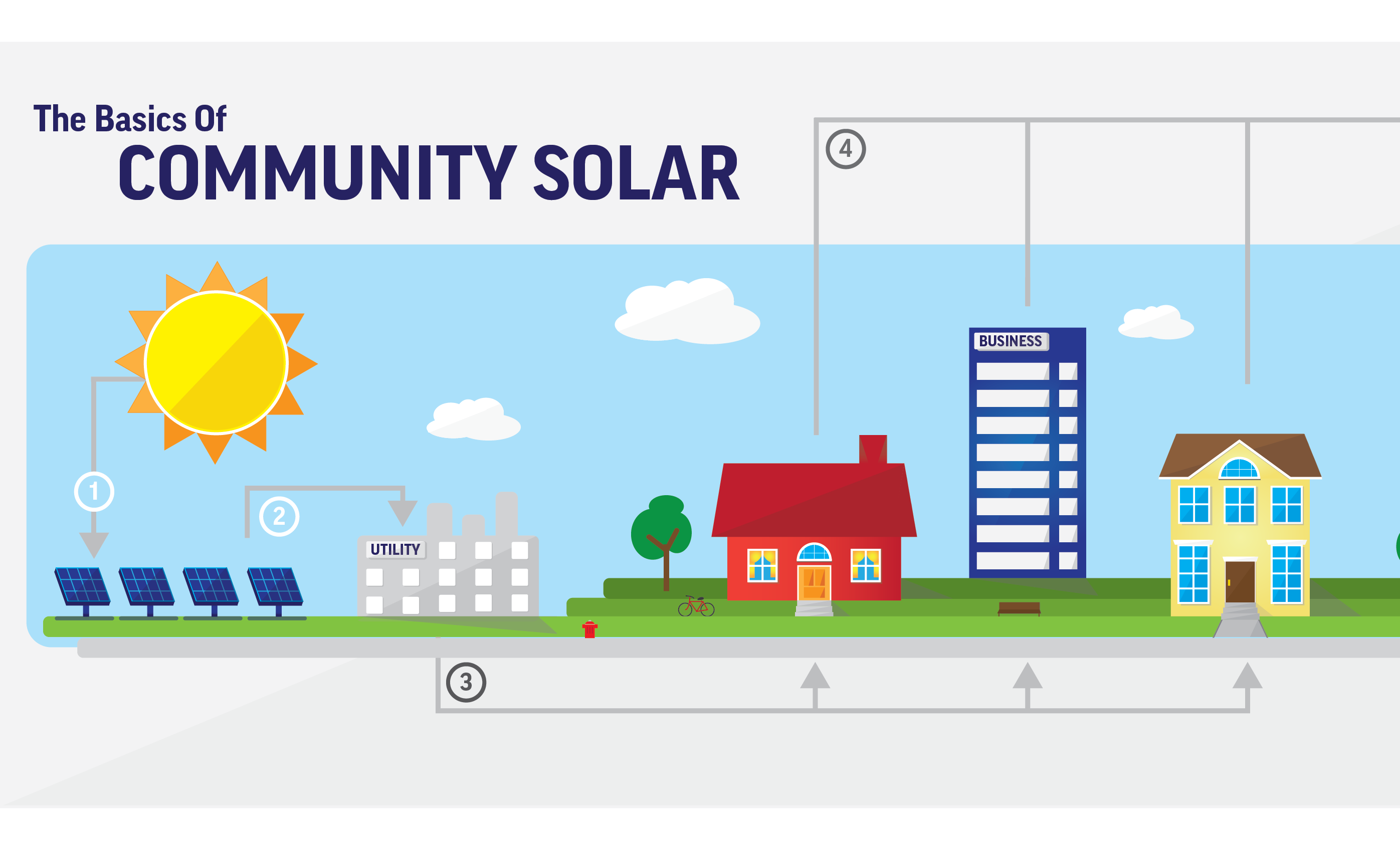

Is Community Solar For You?

A Community Solar project is a group of solar panels installed in a sunny location by a solar developer. Consumers in the area can access the clean energy produced by the panels. This makes solar available to many more people than can access it up to now: not only homeowners, but renters, condo dwellers, small and large businesses, non-profits, churches and other institutions.

A Community Solar project is a group of solar panels installed in a sunny location by a solar developer. Consumers in the area can access the clean energy produced by the panels. This makes solar available to many more people than can access it up to now: not only homeowners, but renters, condo dwellers, small and large businesses, non-profits, churches and other institutions.

And there’s a 10% discount. Energy is delivered to the consumer by the utility the same way it always has been. No fees, no termination penalty.

Community Solar is supported by Sierra Club because it’s clean renewable energy, and it eliminates the main obstacles consumers confront when they want solar: financing, inappropriate orientation, or shading.

Here’s a link to NYSERDA, the NY state government department that is hooking up consumers with Community Solar projects (Please click on ‘Find Community Solar Near You’):

Tuckahoe's Toxic Trench

Want to Get More Active?

Great! Please contact George Klein at (914) 772-3916 or lowerhudson@gmail.com.

Algonquin Pipeline Expansion and Indian Point

Health and Safety Impacts of the Pipeline Expansion

The Algonquin gas transmission pipeline was first installed in the 1950s in NJ, Rockland, Westchester, Putnam, CT, RI, MA.