Quitting our Petroleum Addiction: Top 5 New Bioplastic Innovations

The US generates about 250 million tons of waste a year, and doesn't recycle much of it. The result? Giant ocean gyres of trash, chemicals leaching into the soil, and to top it all off, further consumption of oil--traditional plastic is made from crude oil derivatives. Plastics based on sustainable materials could transform this picture. Widespread use of bioplastics would not only lessen our load on the landfills and use less oil, but also keep us safe from bisphenol A (BPA), a harmful chemical found in petroleum plastics which has been linked to hormone disruption.

While the field of bioplastics is a promising one, most current products are based on labor/energy intensive crops and don’t even fully degrade when disposed of, so the science and tech world is still looking for better options. Here are some of the most promising alternatives to traditional, petroleum based plastics:

1.) Shrimp: This spring, Harvard’s Wyss Institute unveiled the newest version of Shrilk, a shrimp-shell based plastic that decomposes in a few short weeks while simultaneously releasing rich nutrients into the soil. The product uses chitosan, a molecule isolated from the shrimp shells and the second most abundant organic material on earth, instead of petroleum derivatives. (Plus, the shrimp shells are repurposed from fishing industry waste). Unlike the other leading brands of bioplastic, which are expensive and limited in their molding capacity, Shrilk is cheap and easy to manufacture and can be cast into almost any complex 3D shape. The material can be loaded into 3D printers, meaning Shrilk products (like containers and cups) have the capacity to be mass produced and may someday even be printed from home. The project's next step is finding an industrial partner so it can move out of the lab and into a manufacturing facility.

2.) Avocados: The Mexican company Biofase uses the huge quantities of discarded pits from Mexico’s avocado industry to create their bioplastic. The compound isolated from the avocado pits goes into a line of completely decomposable products, as well as resins that can be mixed with petroleum based plastics to make those products more biodegradable. Biofase is working on partnerships with fertilizer companies to provide biodegradable packaging and with supermarkets to provide biodegradable bags. The company was named one of the 20 most promising green companies in Mexico during the Cleantech Challenge Mexico 2012.

3.) Yeast: Verdenzyne is a biotech company that's using yeast, the familiar microorganism that makes our bread rise, to produce the base for many traditional nylon products (toothbrush bristles, fishing line, molding resins, adhesives, etc.). These are currently being made from petroleum intermediates, but yeast can be cultivated to produce Dodecandioic acid (DDDA), the base for production of these plastics. Michigan State University’s Bioeconomy Institute (MBI) worked with the company to create over a metric ton of bio-based DDDA this spring--they’re planning on moving into commercialization soon.

4.) Bacteria: One would think that chemical wastes and other unstable raw materials would belong at the end of the production chain, but SYNPOL is using them at the very beginning. Scientists introduce bacteria to agricultural residues and sewage sludge from water treatment plants, and the bacteria munch away to produce syngases, or synthetically formed gases like methanol, ammonia, and hydrogen. These gases can then be used as a sustainable replacement for petroleum products in the creation of not only plastics, but also adhesives and fuels.

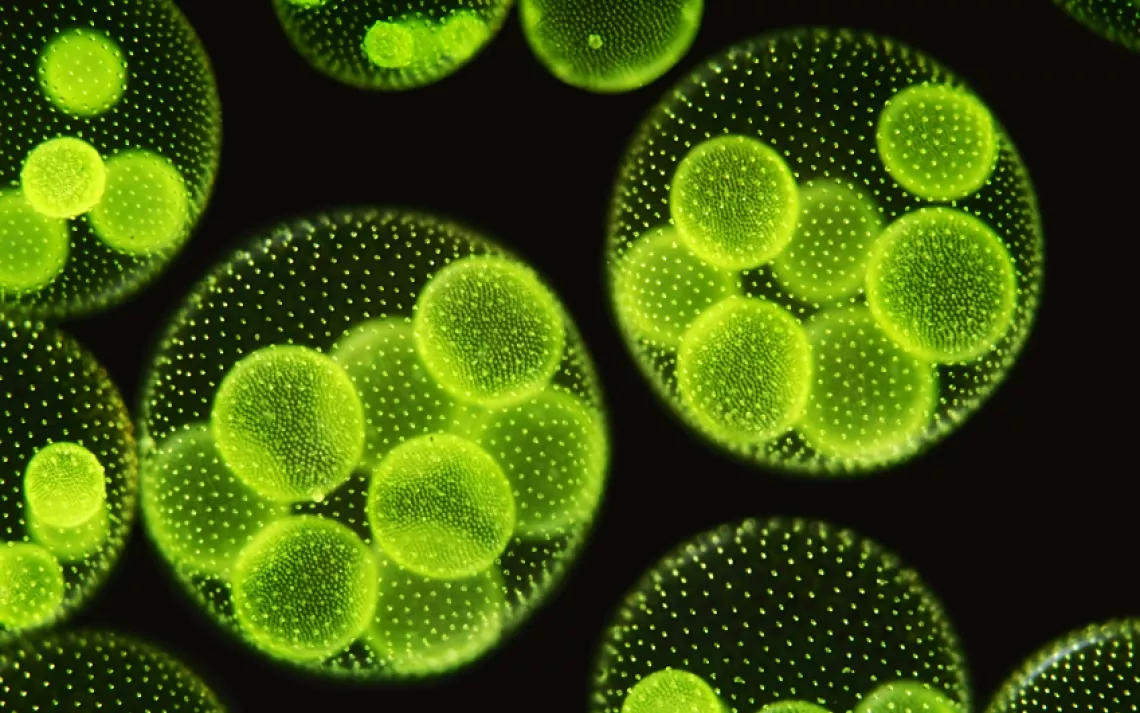

5.) Algae: With the catchiest title of all, the Sustainable Polymers from Algae Sugars and Hydrocarbons (SPLASH) project is creating plastic bases from the green stuff in your pond. SPLASH is developing the algae Botryococcus braunii to yield the hydrocarbons and sugar needed to form the building blocks of a bioplastic. While these basics are currently being produced by the bioplastics industry using mostly sugarcane, algae is a better alternative--it proliferates quickly and needs nothing but sunlight and waste water to grow. For now, this project is far from producing a marketable product, as they are still experimenting with methods of harvesting hydrocarbons, but it’s an exciting prospect.

The Magazine of The Sierra Club

The Magazine of The Sierra Club